Beijing Longyuan Decoration Material Co.,Ltd

Hebei Longteng Technology Co., Ltd

Call +8613261317888

+8618611396905

Email:hblt5566@126.com

Address:Yutian County, Tangshan City, Hebei Province,

Gushu Town Xiangchun Garden, China.

Post Code 064107

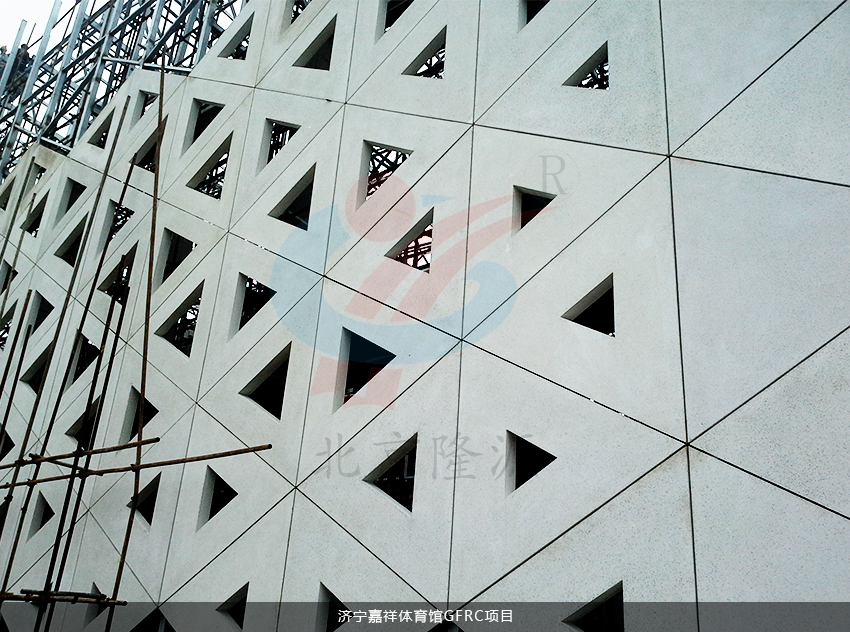

Beijing Longyuan Decorative Materials Co., Ltd. discusses with you why you choose GRC board as decoration material.

In recent years, shopping malls have increasingly demanded more and more standards for housing structures. Following the development of the real estate industry, they have also paid more attention to the exterior decoration of housing construction. The exterior decoration products of the house are endless, not only to deal with the appearance of the building beautification, but also to save the construction period and construction costs. The main components of the mall's primary product materials fall into two categories: GRC materials and EPS materials. Here, we will discuss the new type of polyurethane (PU) material used as exterior wall decoration components in shopping malls today. Regarding the advantages and disadvantages of polyurethane in building wall insulation, there are many opinions in the industry. Therefore, this article will focus on polyurethanes. The material and the traditional GRC material were both compared and analyzed.

First, the difference between the quality of the mall components and the production process

The GRC board is mainly made of alkali-resistant glass fiber as reinforcement auxiliary material, low alkalinity sulphoaluminate cement as cementing material, and yellow sand or quartz sand, which is passed through a glass steel mold, a concrete mold, a plastic mold, a steel mold, a silicone mold, etc. Casting, extrusion, web shop, premix, spray and other processes made of GRC products. Products can be processed continuously according to the molds they hold or remake. GRC components touch the manufacture of product molds, generally have a certain production cycle. The main product lines are: GRC window covers, Roman columns, vases and aquariums, railings, lumbar lines, mountain flowers, sculpture reliefs. After the product equipment has been painted, the GRC series has now been expanded to colorful GRC series products, imitation stone GRC products, and imitation stone GRC components.

The EPS decorative component is a new type of product that expands with the external wall thermal insulation material and the GRC component work. The main material is based on a polystyrene thermal insulation board, and electric wire cutting equipment is used to cut the plate into various lines. The paste-type alkali-resistant mesh cloth was used for surface layer positioning to form a cohesive anti-crack mortar. The product line is primarily lined. The product is mainly supplemented by equipment, and the production cycle is more convenient.

The PU decorative member is based on a polyurethane foam material and is divided into a rigid polyurethane foam, a semi-rigid polyurethane foam and a flexible polyurethane foam material. The rigid polyurethane foam is mainly used for building thermal insulation materials, insulation materials (insulation of pipeline equipment, etc.). The PU performs needle foam molding on steel molds by machines, which requires high molds. Demand for product ejection requires surface painting. The PU line in the product mall is mainly used for interior wall ceilings and mirror frames to replace traditional plaster lines.

Second, the use of differences

GRC decorative components are widely used in the decoration of various types of villas, hotels, residences, and commercial buildings, especially for European style buildings with a messy appearance.

PU line is mainly used for interior wall ceilings and mirror frames to replace traditional plaster lines

Third, quality difference

1, fire prevention function

The polyurethane oxygen index of the polyurethane PU line is as low as 26, and even if the B2 class fire protection (O2 index ≥ 27) cannot be achieved, the fire risk can easily occur during on-site construction. It has adversely affected the owner's normal day's residence after completion. The oxygen index of EPS can reach 35, and can reach Class B1 (O2 index ≥ 32) fireproof.

The GRC component is mainly made of alkali-resistant glass fiber as the reinforcing material, the low-alkalinity sulphoaluminate cement is the cementing material, and the yellow sand or quartz sand constitutes. From the raw material difference, each raw material is the A-class function of the decorative decoration material. For incombustible material.

2, product production and construction application safety

PU component

PU components in the production process: the polyurethane foam molding by temperature, humidity and other climatic conditions, it is necessary to follow the production of the system temperature, polyurethane products need to rely on the interface agent to the underlying adhesion, and then the rear The paint adheres to the interface agent. Full description of the lack of direct bond strength of the polyurethane material to the underlying layer during the foaming process. The interface agent is attributed to the thin coating material. Whether it is the connection of the underlying layer or the application of anti-cracking putty, it must rely on it. It can be seen that the molding of the polyurethane line is divided into many layers, and the integrity of the system and the bonding strength are affected. Very bad influence. The PU lines are all linear structures, and they need to be squeezed and fixed at the factory to prevent deformation.

In the component equipment: due to the polyurethane mold requirements for the sealing treatment, the embedded parts used in the equipment need to be embedded in the product after the second pre-embedded, there is a certain risk on the equipment itself, such as the use of dragon skeleton Nail-fixing can not meet the load-bearing requirements with regard to the load-bearing weight of some windows on the window sills. As far as buildings are concerned, after all, it is necessary to reserve walls, holes, air-conditioning holes, and so on. Polyurethane is used for foam molding of machinery and equipment in the factory. The seams of lines and lines cannot be jointed with PU material of the same material, and the repairability and repairability of the latter are relatively poor. After the dismantling of the scaffolding in the new construction, the construction problems caused by the repair and addition of the remaining pipe holes were unexpected to the polyurethane system. Polyurethane line production and construction do not turn over the net or grid cloth processing, and PU lines and wall sections can not be cemented with the traditional cement mortar, for the future wall cracking, leakage embedded risk.

In terms of use, it can only be applied to some wall lines, and it is not allowed to use handrails and vases that are more important in transportation applications. The aging phenomenon of polyurethane materials is greatly affected by ultraviolet light and temperature. Therefore, it is easy to attack brittle cracks and deformations due to the accidental exposure to the outside of the window openings after the product is released to the outside of the construction equipment and construction site, and after the paint is applied. The impact problem will cause the polyurethane plastics to become brittle and deformed into impatience and impact resistance during this period, which will bring risks to the future use of the ductility and the use of the number of life.

On the equipment: GRC can be produced and cut in large blocks, with concise and diversified equipment methods, all of which are factory prefabricated, which is conducive to on-site construction and greatly shortens the construction period. Product embedded parts are embedded in the product for one-time embedding to improve the robustness of the equipment. The auxiliary materials for the equipment are all fixed with galvanized iron and steel parts, all of which can meet the requirements of anti-corrosion load-bearing. Joint joints of component parts are selected by using grid cloth and GRC material co-elastic adhesive of the same material for joint processing.

In terms of use: According to the different needs of customers and planners, any artistic styling can be performed to perfectly complete the planning hopes of the planner. The bulk density of GRC is about 1.8-1.9, 8mm standard GRC board component is only 15kg, compressive strength exceeds 40Mpa, bending strength exceeds 34Mpa, greatly exceeds the world standard requirements. The thinnest GRC plate can be 5mm, the standard width is 900mm and 1200mm, and the length is not limited. It can also be made into 5mm to any thickness. It can satisfy the transportation conditions at any scale. It can also be used as a vase rail handrail with high solid strength, and it can be used with concrete structures.

GRC component

In the production process: GRC decorative components are mainly alkali-resistant glass fiber reinforced auxiliary materials, low alkalinity sulphoaluminate cement is a cementing material, and yellow sand or quartz sand, through the glass steel mold, concrete mold, plastic mold, steel Molds, silicone molds, etc. have been made into GRC products through casting, extrusion, web shop, pre-mixing, spraying and other processes, which can produce products with rich shapes and various textures. Raw materials do not contain radioactive nuclear elements and are national class A environmental protection materials with radionuclide content. All raw materials are non-combustible materials and have been tested as Class A1 fireproof materials. When immersed in water for a long time, the shape and safety factor of GRC materials are changed little, and the structure and function are not changed. The dry and wet deformation of the material is less than 0.123%. After many experiments have proved that it has superior durability, is not afraid of ultraviolet radiation, can withstand wind, sun, rain, and weather resistance is much higher than the general building materials. Depending on the thickness of the GRC material and the way the surface is treated, excellent sound and sound absorption can be achieved. Coupled with its light weight and high strength, it is stronger than other materials to withstand earthquake shocks.

010-80857304

Beijing Longyuan Decoration Material Co.,Ltd Hebei Longteng Technology Co., Ltd Call +8613261317888 +8618611396905 Email:longtengkeji00@outlook.com Address:Yutian County, Tangshan City, Hebei Province, Gushu Town Xiangchun Garden, China. Post Code 064107 |

Sweep the attention |